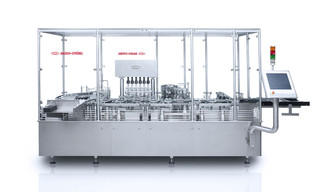

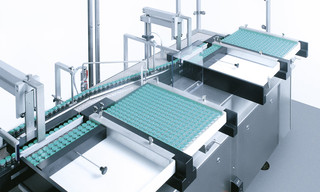

Filling and closing machines

FVF series

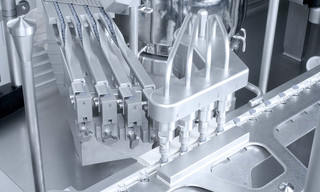

The FVF series consists of compact lines for filling and closing vials and similar stable bottles made of glass, plastic or metal. The machine is designed for a broad range of applications. Both liquid and powder products can be filled by using different dosing systems. The containers are conveyed through the work area in an intermittent motion by a walking beam system which handles the containers particularly gently. The number of transport positions is variable, which means that these systems have a wide processing range. A further special feature: 100% IPC at full output.

Maximum safety in HPAPI and ADC processing with proven filling solutions

Maximum safety in HPAPI and ADC processing with proven filling solutions

HIGHLIGHTS

- Liquid or powder products

- Gentle container transport

- 100 % IPC at full output

- Up to two different types of closure

| Type of machine | Output | Processing range |

|---|---|---|

| FVF5060 |

|

|

| FVF5061 |

|

|

| FVF5062 |

|

|

| FVF5063 |

|

|

Easy and centralized operation

Short set-up time

Pharmaceutical design

Gentle container transport

- Barrier systems – RABS and cleanroom isolator

- Processing non-stable containers

- Various dosing systems (e.g. peristaltic pumps, time-pressure dosing system, powder dosing systems etc.)

- SIP/CIP-compatible dosing components

- ECOfill

- Zero-loss start-up and running empty with minimal product loss

- In-Process Control (IPC)

- Sample discharge

- Closure feed from supply system

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

ECOfill increases the number of vials filled per batch, maximizing your profit margin.

ECOfill ensures that effective use is made of your product batch. It doses your product within ultra-close dosing tolerances. All containers in a batch are filled to the optimal level so that, at most, only the last container may need to be rejected. The ECOfill dosing system consists of two dosing stations and works on a 2-stage dosing principle (rough dosing and fine dosing). It covers all phases of production – from start-up and production to running empty.

Benefits of the ECOfill dosing system:

- "Benefit vials" – the product saved dose by dose

- No need for manual intervention in the dosing area, e.g. during start-up or running empty

- Ultra-close dosing tolerances

- Availability from batch sizes as small as 1

- Optimal product utilization

- Resource-friendly technology

ADVANCEDfill ensures that optimal use is made of your product batch.

ADVANCEDfill is a highly effective solution for processing your product. All containers in a batch are filled to the optimal level so that, at most, only the last container may need to be rejected. The ADVANCEDfill dosing system is equipped with a freely positionable needle holder. Product is dispensed directly into containers on the scales during start-up and running empty. This allows dose quantity to be monitored and setpoint deviations to be corrected in situ.

Benefits of the ADVANCEDfill dosing system:

- No need for manual intervention in the dosing area, e.g. during start-up or running empty

- Optimal product utilization

- Availability from batch sizes as small as 1

- Resource-friendly technology

smartline

Are you looking for an approved off the shelf machine concept with short delivery times, but still want to be able to optimize your line to suit your specific needs?By choosing our smartline concept you can select your personal solution from pre-engineered options and still maintain your flexibility. smartline guarantees a more efficient project workflow. Maintenance, qualification and spare parts procurement are not only faster, but also easier to handle over the entire life cycle of the line. Eliminate time-consuming engineering phases and benefit from reliable solutions that come ready to use straight out of the box.