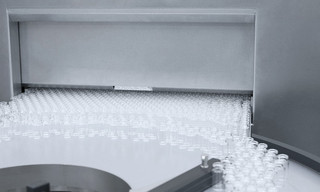

Sterilizing tunnel

DHT series

The sterilizing tunnels of the DHT series dry, sterilize and depyrogenize glass containers using a low-turbulence vertical air flow. The sterilizing-grade filters or integrated high-efficiency particulate air filters (HEPA filters) do not require any sealing on the air discharge side. Special hot gas filters in the sterilization zone produce a cleanroom class A atmosphere in all operating conditions (even during the pre-heating and cooling phases). The tunnels have multiple insulation layers to prevent heat loss and maximize energy efficiency.

HIGHLIGHTS

- Low-turbulence, vertical air flow for optimal heat transfer

- Precise maintenance of production parameters

- Gentle container heating

- High energy efficiency

| Type of machine | Output | Processing range |

|---|---|---|

| DHT2431 |

|

|

| DHT2550 |

|

|

| DHT3670 |

|

|

| DHT40125 |

|

|

| DHT49125 |

|

|

B+S hot gas filter with long filter life

Easy and centralized operation

Pharmaceutical design

- Transverse conveyor belt with transfer mechanism for stable containers at the tunnel infeed

- Heating timer for pre-heating prior to operation

- Cleanroom partition

- Special Bausch+Ströbel hot air filters in the pre-heating and cooling zones

- Vane wheel anemometers for air velocity measurement in the pre-heating, sterilizing and cooling zones, with display on the operating panel or recording on a multichannel process recorder

- Equipment to monitor the differential pressure between the cleanroom and the cooling zone

- Equipment to monitor the max. dwell time of the containers in the high-temperature environment, with discharge of processed containers to the machine downstream (DHT 4432/DHT 5732/DHT 5764)

- Heat exchanger (for cooling the circulating air in the cooling zone)

- Hot-sterilizable cooling zone equipped with identical Bausch+Ströbel hot gas filter to sterilizing zone

- Recording of conveyor belt speed on a multichannel process recorder

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

Energy efficiency

Energy saving is also a top priority at B+S.- The sterilization process offers the greatest potential for reducing line energy consumption.

- Multilayer insulation is used to minimize heat loss in the tunnel tube.

- The pressure cascade is optimized to minimize the heat loss resulting from cross-flow between zones.

- Air is recirculated within the sterilization zone, eliminating the need for an external air supply and maximizing energy efficiency.

- Thanks to these and various other measures, B+S consistently achieves exceptional energy efficiency, setting the benchmark in the market.