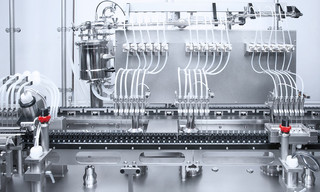

Filling and closing machines

KFM series

The machines and lines of the KFM series have been developed for processing cartridges. The machine concept provides scope for intermittent-motion rotary machines as well as continuous and intermittent-motion linear machines. Before filling, the plunger stoppers are inserted into the cartridges from below. The dosing station is designed to process liquid products using rotary piston pumps. However, it can also be equipped with alternative dosing technology such as peristaltic pumps or a time-pressure dosing system. The cartridges are filled to the brim in 2 stages by prefilling the cylindrical part of the cartridge, followed by final filling up to the top of the cartridge. The cartridges are then closed with crimp caps with a rubber seal.

Container transport without glass-to-glass contact

A special transport system transports the cartridges individually, safely and gently from the start to the end of the primary packaging process. This system ensures that the cartridges do not come into contact with one another at any time.

Container transport without glass-to-glass contact

A special transport system transports the cartridges individually, safely and gently from the start to the end of the primary packaging process. This system ensures that the cartridges do not come into contact with one another at any time.

HIGHLIGHTS

- High process reliability

- Pharmaceutical design

- Easy and centralized operation

- Optimal laminar air flow

| Type of machine | Output | Processing range |

|---|---|---|

| KFM4008 |

|

|

| KFM6012 |

|

|

| KFM8016 |

|

|

Compact design

Low-particle closure feed

Gentle container transport

- Barrier systems – RABS and cleanroom isolator

- Insertion of mixing beads

- Alternative dosing systems (e.g. peristaltic pumps, time-pressure dosing system)

- SIP/CIP-compatible dosing components

- Gas-flushing stations

- Various supply hoppers

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

CIP/SIP

"Cleaning in place – sterilizing in place" is a system for cleaning and/or sterilizing product-carrying parts as installed. Our CIP/SIP system offers a high level of process reliability while saving work and time, as well as cutting cleaning and sterilization costs.All parts which come into contact with the product are rinsed intensively with suitable cleaning media. There is no need to remove any parts. Once the cleaning and sterilization process has been completed, the entire system is cooled and kept under vacuum until the start of production. All applicable technical and pharmaceutical regulations, such as DIN, GMP and FDA, are observed and applied.

Dosing systems

Rotary piston pumpsThe rotary piston pumps comprise only two parts. The dose is defined by the pump stroke setting. They are self-priming and dispense pharmaceutical products very gently and with great precision.

Single-hose peristaltic pumps

Only one product hose is required from the product vessel to the dosing needle. The single-hose peristaltic pumps do not require a Y-manifold, which means that the dosing system itself is very straightforward and easy to use.

Time/pressure dosing system

Product is supplied from a dosing vessel equipped with a precision pressure controller. Only one product hose is required from the pressure controller to the dosing needle. This electronically controlled dosing process allows production data to be acquired and documented.

Barrier systems – RABS

Aseptic ambient conditions free of contamination can be created using RABS (Restricted Access Barrier Systems).

- Passive RABS

- Active RABS

- Closed RABS

- Isolator

Taking the building and room situation into account, these systems provide optimum air flow conditions.