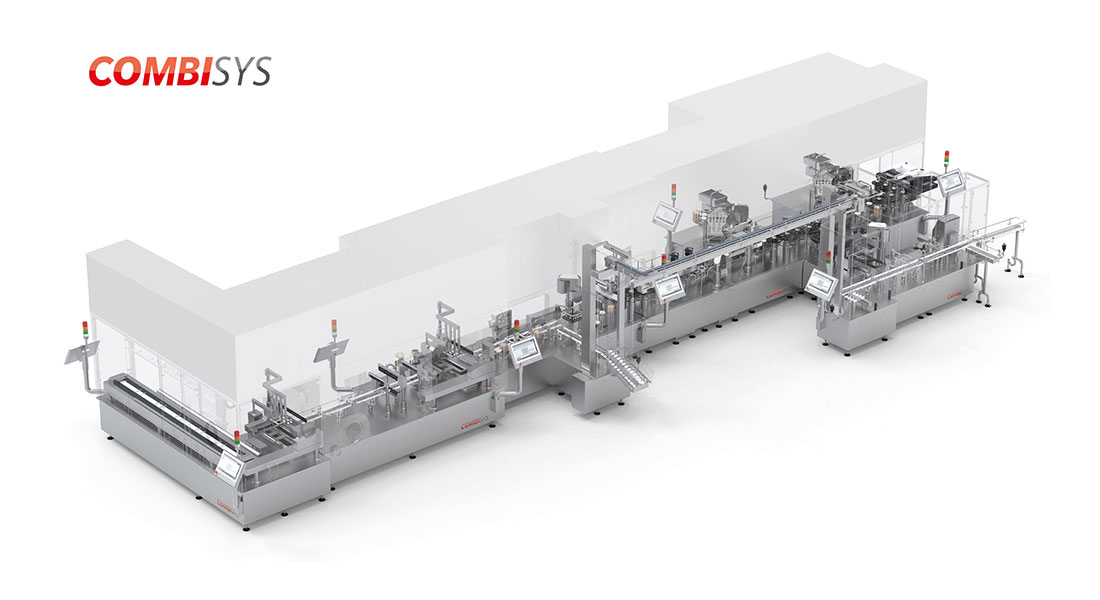

CombiSys: A system solution combining efficiency and productivity.

As part of our ongoing efforts to enhance our successful Combisys portfolio, we’re excited to introduce a new and innovative technology to the B+S product range. This innovative technology excels in combined processing and handling complex filling requirements while offering optimal cleanability and hygiene design.

We give you a first glimpse of what you can expect from our upcoming product developments.

Following on from the VarioSys production system combining machine modules with an isolator, special machine manufacturer Bausch+Ströbel is now launching another system solution: CombiSys. It allows a variety of container types to be processed on a single platform with outputs of up to 12000 containers per hour and 100 percent IPC. The focus here is particularly on the “Zero Reject Principle”. The modular design concept and use of standardized components cut engineering and production lead time, allowing quicker delivery of the final product to the customer.

The CombiSys work stations are all based on the same functional principle, which greatly simplifies changing size parts and maintenance. CombiSys requires only a few size parts, making it easy to reconfigure for a different container type and user-friendly – CombiSys is configured for in-nest processing of pre-sterilized syringes, vials or cartridges (RTU containers).

Flexibility:

- One platform for various container types

- 100 % IPC at full output

- Up to 3 dosing systems

- RABS / isolator compatible

- Fewer size parts

- Easy maintenance and resource-friendly parts management

3 dosing systems in 1 machine

Today, flexibility is key – not only for packaging materials but also for dosing. If different dosing methods have been validated for pharmaceuticals, these can only be produced on the same line if multiple dosing stations are available from the start – or else the system has to be modified. This can now be done without the need for any modification using our "Multi-Dosing Unit" with integrated peristaltic pumps, rotary piston pumps and a time-pressure dosing system. This unit features a central drive system making for a highly compact and space-saving design.CombiSys is an ideal solution for contract fillers and pharmaceutical manufacturers who require a high degree of flexibility and for whom the scalability of the machines used is a competitive factor.