// Shaping the future of pharmaceutical production: your RTU containers, our expertise. ///

- Proven and continuously improved technology

- Gentle transport for optimal processing accuracy

- Select from a range of filling systems designed for maximum filling precision

- Our machines are designed for maximum ease of use and excellent accessibility, facilitating quick size changes

Bausch+Ströbel - the leading manufacturer of machines for processing ready-to-use packaging (RTU) - offers you perfect solutions tailored to your pharmaceutical process. With decades of expertise in both semi-automatic and fully automatic machines catering to the low to high-output ranges, we set the global benchmark.

Our commitment to continuous technological development ensures the highest level of precision in filling and closing processes. We prioritize the gentle transport of containers without glass-to-metal contact, while offering maximum flexibility through a selection of high-precision filling systems.

Your future in pharmaceutical product begins with Bausch+Ströbel. Count on our well-established expertise and cutting-edge technology to consistently meet the highest standards. Making your pharmaceutical production more efficient and future-ready than ever before.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from the experience we have gained in the course of delivering more than 15,000 machines to customers the world over. With our global network of distributors, we are reliable partner with a strong focus on customer service.

Our 2,300-strong global workforce is dedicated to ensuring your success and providing you with support throughout the entire life cycle of your machines and production lines. We look forward to collaborating with you on the ideal solution for your product.

Our commitment to continuous technological development ensures the highest level of precision in filling and closing processes. We prioritize the gentle transport of containers without glass-to-metal contact, while offering maximum flexibility through a selection of high-precision filling systems.

Your future in pharmaceutical product begins with Bausch+Ströbel. Count on our well-established expertise and cutting-edge technology to consistently meet the highest standards. Making your pharmaceutical production more efficient and future-ready than ever before.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from the experience we have gained in the course of delivering more than 15,000 machines to customers the world over. With our global network of distributors, we are reliable partner with a strong focus on customer service.

Our 2,300-strong global workforce is dedicated to ensuring your success and providing you with support throughout the entire life cycle of your machines and production lines. We look forward to collaborating with you on the ideal solution for your product.

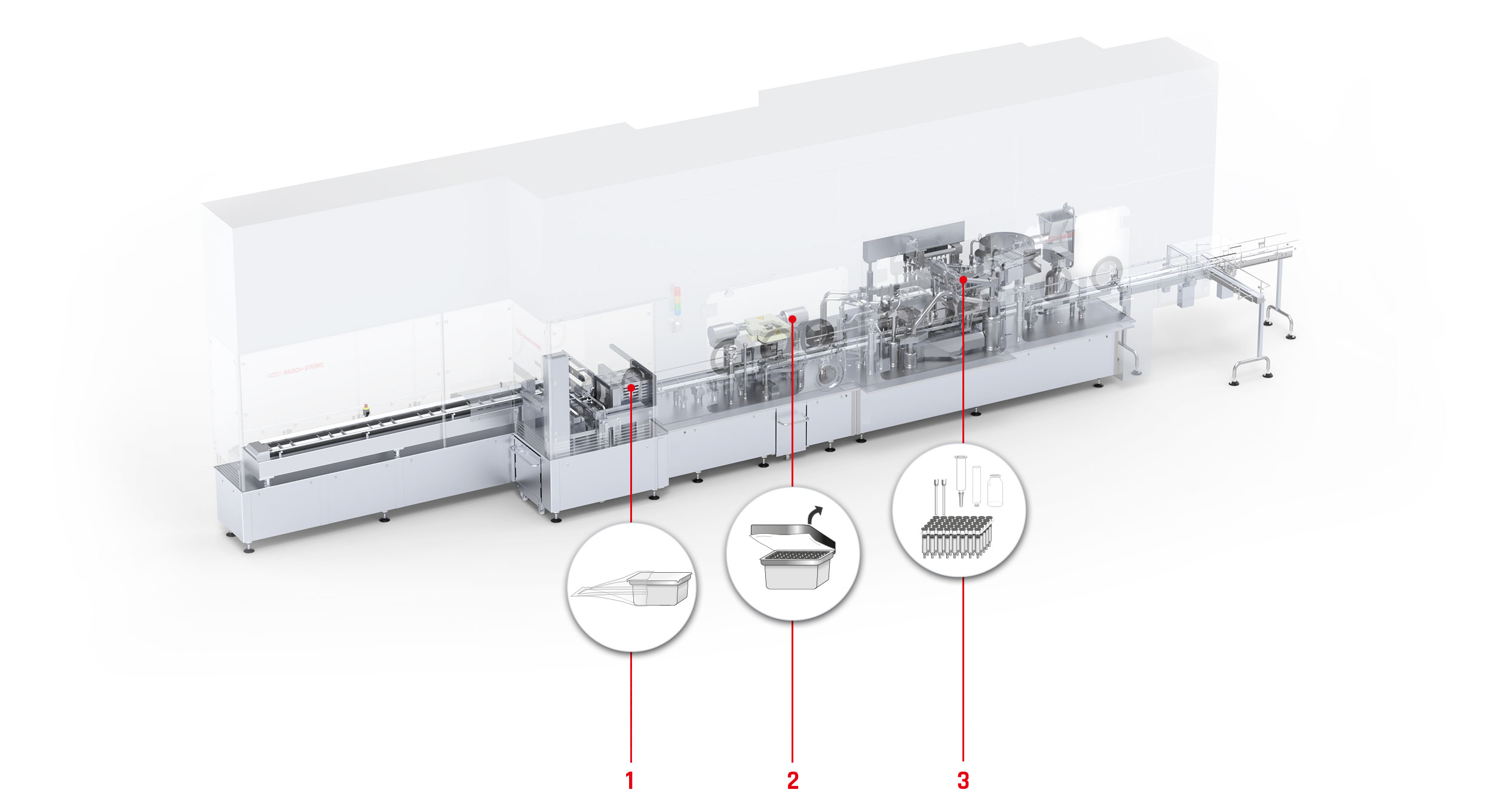

- Our particle-free transport system ensures optimal process reliability

- Fully automatic debagging process

- Automated disposal of bags into a removable collecting bin

- Automated size adjustment throughout the entire machine

- Principle of "no size parts"

- Tub debagging and transfer based on the No-Touch Principle

- Our particle-free transport system ensures optimal process reliability

- Automatic removal of the lid and liner from the tub

- Automated disposal of the lid and liner into a removable collecting bin

- Our dosing systems offer the highest level of accuracy for any product

– Rotary piston pump

– Peristaltic pump

– Time-pressure dosing - oRABS, cRABS and isolator compatible

- Low-particle transport system for safe and gentle container transport

- Machine concept optimized for laminar flow (LF)

- Fully automated statistical in-process control (IPC) for maximum filling quality

- Vacuum-assisted dosing and closing of containers

- Gas flushing with a controlled amount of gas during filling and closing

- Options for COP (Cleaning Out of Place) and CIP/SIP (Cleaning/Sterilizing In Place