// Take your first step towards turning research into innovative products. ///

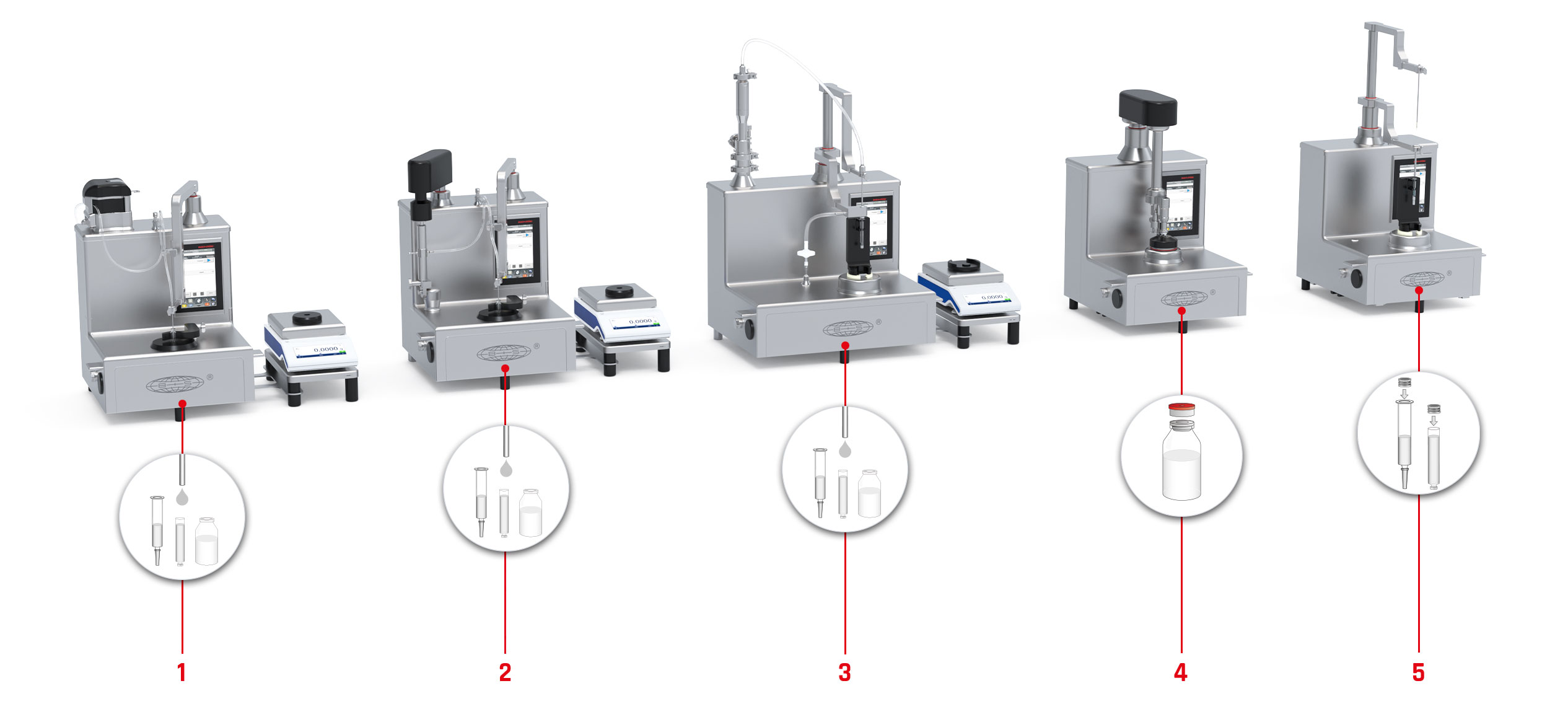

- Processing of various packaging materials and special applications

- Easy scale-up due to filling and closing technology being identical to fully automatic high speed machines

- Simple operation via a central touch screen panel, where all settings can be entered and saved

- Reproducibility and flexibility due to servo technology

- H2O2 decontamination resistant

Whether for drug development, clinical filling or micro-batch production such as in the field of cell therapy, our table-top machines are widely used by pharmaceutical companies, research laboratories, clinics and start-ups. What excites users is the incredible flexibility of our machines in terms of both packaging materials and filling media. We have a solution for everything from liquids through highly viscous media to powdered products.

Our table-top machines are highly reliable and feature an intuitive touch screen for maximum ease of operation. Although they are so user-friendly, they are resistant to H2O2 decontamination, making them ideally suited to use in an isolator.

Our table-top machines are often used for filling at the start of a high-volume production process because they utilize the same filling technology as our high-volume machines, ensuring all procedures are reproducible. This means that processes can be scaled up very easily.

Our table-top machines are highly reliable and feature an intuitive touch screen for maximum ease of operation. Although they are so user-friendly, they are resistant to H2O2 decontamination, making them ideally suited to use in an isolator.

Our table-top machines are often used for filling at the start of a high-volume production process because they utilize the same filling technology as our high-volume machines, ensuring all procedures are reproducible. This means that processes can be scaled up very easily.

Features

Optional features

Features Peristaltic Pump

For more information about the B+S machine portfolio, just click here

- Single-hose peristaltic pump

- Servo needle movement

- IPC scale – up to 100 % IPC

- Automatic feedback adjustment of the dose

- Two-hand control for operator safety

Optional features

- ADVANCEDfill: Start-up without product loss and running empty with minor product loss

- Vacuum-assisted filling

Features Peristaltic Pump

- Ideal for single-use dosing systems

- Gentle product handling (minimized shear stress)

- Fast product change as only hoses and needle have to be exchanged

- No product contacting mechanical parts

- Dosing range from 0.1 ml

- High dosing accuracy

- Servo technology provides high flexibility

- Adjustment of all dosing parameters at the HMI

- Integrated drip retraction

- No influence of product temperature on filling result

For more information about the B+S machine portfolio, just click here

Features

Optional features

Features Rotary Piston Pump

For more information about the B+S machine portfolio, just click here

- Rotary piston pump

- Servo needle movement

- IPC scale – up to 100 % IPC

- Automatic feedback adjustment of the dose

- Two-hand control for operator safety

Optional features

- Vacuum-assisted filling

Features Rotary Piston Pump

- High dosing accuracy: ± 0,5 %(dosing volume > 0,02 ml)

- Product viscosities up to 70,000 cP

- Servo technology provides high flexibility

- Adjustment of all dosing parameters at the HMI

- Integrated drip retraction

- No valves, no seals and minimized dead volume due to precise manufacturing process

- Autoclavable

For more information about the B+S machine portfolio, just click here

Features

Optional features

- ViscoTec pump for highly viscous products up to 5,000,000 cP

- Servo needle movement

- IPC scale – up to 100 % IPC

- Automatic feedback adjustment of the dose

- Two-hand control for operator safety

Optional features

- Vacuum-assisted filling

For more information about the B+S machine portfolio, just click here

Features

Optional features

For more information about the B+S machine portfolio, just click here

- Rotation of containers during closing by servo

- Adjustable crimping tool lift by servo

- Adjustable crimping disc movement by servo

- Adjustable crimping speed

- Crimping pressure adjustment

- Two-hand control for operator safety

Optional features

- Spacing roller at the crimping disc

For more information about the B+S machine portfolio, just click here

Features

Optional features

For more information about the B+S machine portfolio, just click here

- Adjustable plunger insertion speed by servo

- Adjustable plunger depth by servo

- Two-hand control for operator safety

Optional features

- Gas-flushing during plunger insertion

- Vacuum-assisted plunger insertion

- Vacuum-assisted plunger insertion by vacuum chamber for coated plungers

For more information about the B+S machine portfolio, just click here

In close collaboration with SCHOTT Pharma

Flexibility is key when it comes to drug delivery solutions. SCHOTT Pharma offers an extensive and scientifically proven product portfolio including vials, syringes, cartridges, and Fast Track Kits. It´s products always ensure quality and safety when choosing between non-sterilized or ready-to-use products, which cover a wide range of filling lines.

You too can benefit from:

You too can benefit from:

- Easy access

- Fast delivery

- Proven and certified products

- Competent customer care