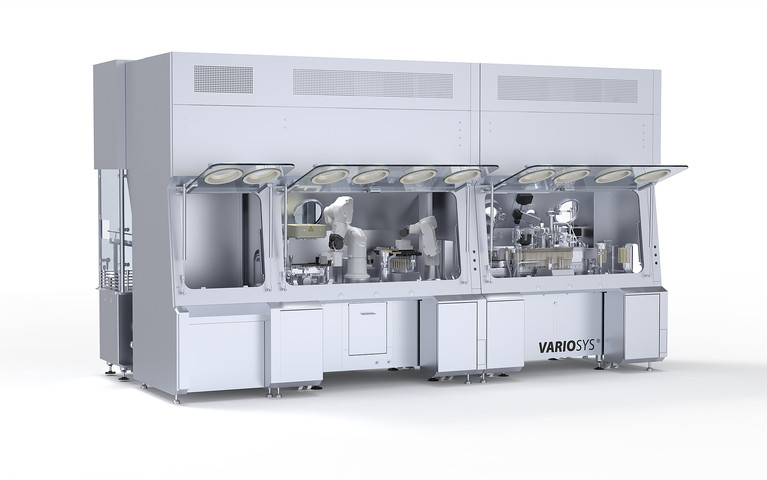

10 Years of VarioSys

Veröffentlicht: 5/13/24

It's been ten years since the ultra-flexible VarioSys production system was launched on the market. This system not only enables the individual customization of a special isolator with production modules like filling or closing machines but also allows these machines to be interlinked, creating seamless production lines. In commemoration of this anniversary, Bausch+Ströbel has introduced a cutting-edge module to the market, setting a new standard in flexibility. Similar to its predecessor, this latest addition to the VarioSys lineup can handle both syringes and cartridges directly from the nest. Notably, it also features 100% In-process Control (IPC), ensuring quality without compromising performance. The key is an all-new container transport system.

Ten years ago, the impetus for the development of VarioSys was provided by Boehringer Ingelheim Pharma. They were seeking flexible production solutions for their US site in Fremont, California. What they needed was a highly versatile system capable of processing various administration forms – syringes, cartridges, and vials – while accommodating different filling quantities within a single isolator. This approach contrasted sharply with the traditional method of installing separate filling and closing machines permanently within an isolator for each type of container. This system, developed in collaboration with Bausch+Ströbel and the isolator manufacturer Skan, is already being successfully utilized by numerous pharmaceutical companies worldwide.

Over the years, VarioSys has been continuously expanded and improved. The newly developed SFM 5205 module fills and closes ready-to use (RTU) containers, including syringes and cartridges, without requiring module replacement. The connected VarioSys DDM module handles the denesting and renesting processes.

The SFM also provides flexibility in dosing, offering a selection of dosing systems including a peristaltic pump, a rotary piston pump, or a time-pressure dosing system. The proven multi-dosing system is also available as an option.

The performance is equally impressive, achieving outputs as high as 4500 containers per hour. The newly developed module offers In-process Control (IPC) for each individual container without any performance loss. In addition to guaranteeing precise dosing for each container (AdvancedFill), the position of the stopper on each individual container can be checked. This 100 % In-process Control (IPC) configuration is enabled by a newly developed individual container transport system.

The new module will be introduced to a broader audience for the first time at Achema 2024, alongside numerous other new and advanced developments from Bausch+Ströbel, all under the theme "Next is now - shaping the future together".