// Looking for an experienced and dependable supplier for your vial processing line? Then B+S is the right partner for you. ///

- Proven cutting-edge technology

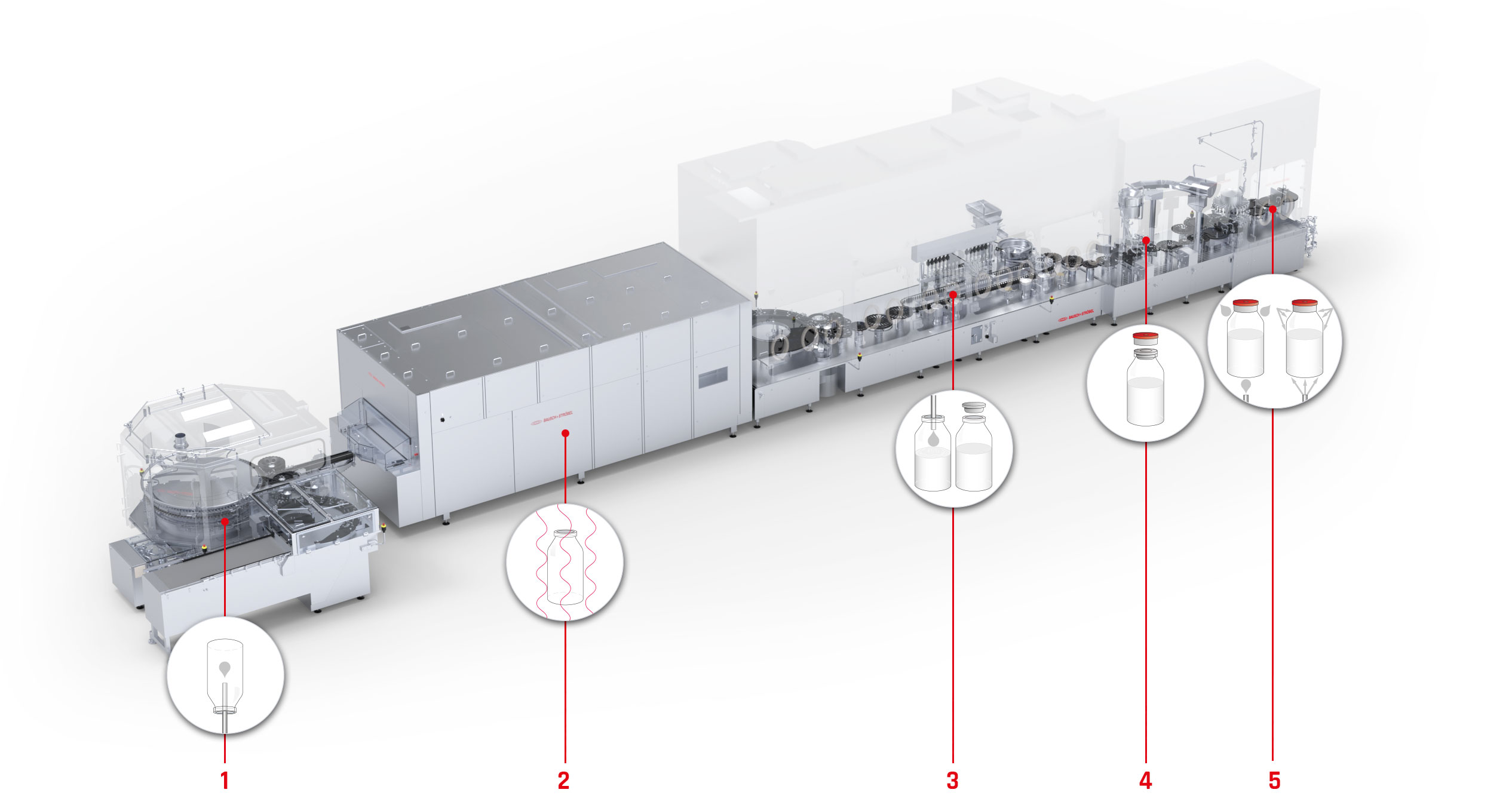

- Wide range of processing applications from vials to infusion bottles

- Highest filling precision with a choice of multiple filling systems

- Gentle vial transport

- High reliability with our Zero Reject Principle

- Maximum ease of use with good accessibility for quick size changes

State-of-the-art vial processing systems made by Bausch+Ströbel are used in pharmaceutical production all over the world. Our customers, from high-tech manufacturers, CMOs, biotech companies, R&D labs and OTC pharmaceutical producers to packaging manufacturers and start-ups, benefit from our decades-long experience. To create value for our customers, we are constantly improving our systems to ensure exact and gentle processing of vials. It goes without saying that our systems provide gentle container transport without glass-to-metal contact, pick and place stopper assembly, a choice of multiple filling configurations, 100% IPC without loss of performance – and much more besides.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from the experience we have gained in the course of delivering more than 13,000 machines to customers the world over. With our global network of distributors, we are a reliable partner with a strong focus on customer service.

Our 2100-strong global workforce is committed to working for your success and supporting you throughout the life cycle of your machines and production lines. We look forward to working together with you on the best solution for your product.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from the experience we have gained in the course of delivering more than 13,000 machines to customers the world over. With our global network of distributors, we are a reliable partner with a strong focus on customer service.

Our 2100-strong global workforce is committed to working for your success and supporting you throughout the life cycle of your machines and production lines. We look forward to working together with you on the best solution for your product.

- Intensive inner and outer cleaning of vials – process steps are reproducible at any time and rewashing is possible

- Smooth and gentle vial transport

- ECOwash saves media resources and reduces noise emissions

- The cleaning program is freely configurable at each of the stations in the line

- Cleaning media are recycled to minimize consumption

- Safe and reliable sterilization and depyrogenation

- Gentle heating and cooling of glass containers

- Pressure cascade system with optimized energy efficiency and savings

- Extremely long filter life (Longlife)

- Easy integration into production lines and facilities

- Higher process reliability through automated filter integrity testing (DEHS)

- The best dosing system with the highest accuracy for any product

– Rotary piston pump

– Peristaltic pump

– Time-pressure dosing

– Powder dosing system

– Modular multi-dosing system - Walking beam transport system for safe and gentle container transport

- 100 % IPC at full capacity

- Reliable stopper insertion using pick-and-place technology

- AdvanceFill through ADVANCEDfill and Re-Stoppering for minimum product loss

- ADVANCEDflush reduces the residual oxygen level to below 1 %

- oRABS, cRABS and isolator compatible

- Hygenic design for optimal aseptic handling

- COP (Cleaning Out of Place) or CIP/SIP (Cleaning/Sterilizing In Place) is possible

- Reliable and gentle continuous-operation closing system

- User friendly with crimping pressure display and adjustment on the HMI touch screen

- Low-particle-emission cap feed

- cRABS and isolator compatible

- Hygenic design for optimal aseptic handling

- Higher process reliability thanks to cap printing and camera inspection systems

- Ring jets ensure effective and thorough cleaning of vials (also suitable for high-potency products)

- Top-to-bottom container drying (cap protection)

- Choose between low-pressure cleaning or high-pressure cleaning

- WIP (Washing In Place) – complete spray down without opening machine guard

- Magnetic transport system (XTS)

- cRABS and isolator compatible

- Hygenic design for optimal aseptic handling