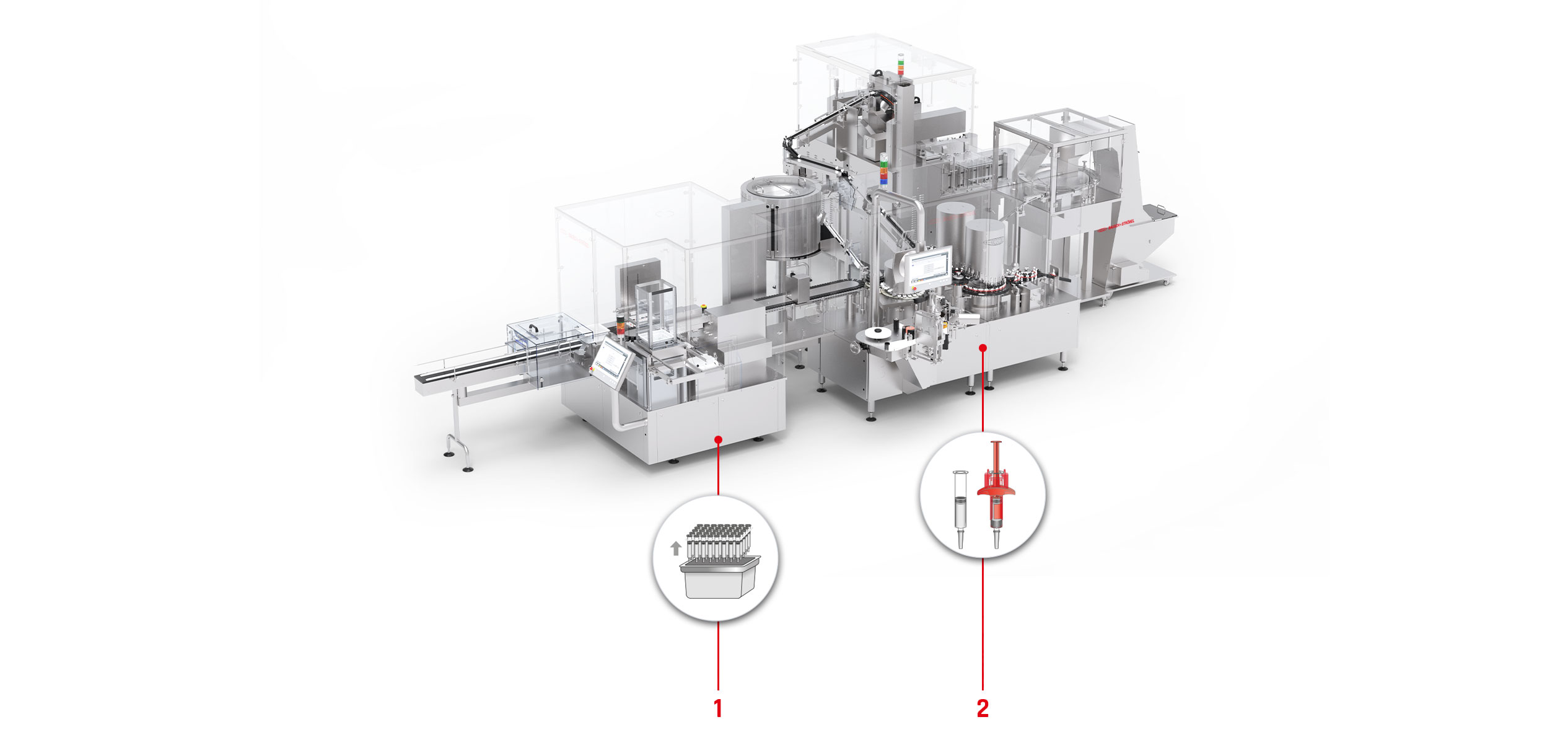

// Introducing our compact all-in-one machines that combine precision labeling and reliable assembly all on a single platform. ///

- Proven and constantly evolving technology

- Easy linking and integration into downstream packaging lines

- Connectivity to upstream syringe inspection machine

- Gentle individual transport without glass-to-glass contact

- Ultra-compact design, even in the maximum configuration

Our core area of expertise is our high-precision filling and sealing process, but rest assured that your container is in capable hands with us even after this process is completed. We also have access to long-tested and proven secondary packaging technologies that we have continuously refined and improved over time. At Bausch+Ströbel, we can offer a highly flexible platform that can meet a wide range of requirements - from simply applying a label with coding to performing multiple syringe assembly steps.

In addition to the gentle removal of containers from the syringe nest and subsequent transport to assembly stations, our main focus is on the easy integration of our solutions into downstream packaging lines.

Our example shows an highly compact system designed to allow the assembly of plunger rods, backstops and needle guard systems including an extended finger flange on just one machine platform.

For more information about the B+S machine portfolio for secondary packaging, just click here

In addition to the gentle removal of containers from the syringe nest and subsequent transport to assembly stations, our main focus is on the easy integration of our solutions into downstream packaging lines.

Our example shows an highly compact system designed to allow the assembly of plunger rods, backstops and needle guard systems including an extended finger flange on just one machine platform.

For more information about the B+S machine portfolio for secondary packaging, just click here

- Nests are safely removed from the syringe tubs

- Syringes are removed from the nests in rows at a rate of up to 400 syringes per minute

- Syringes are inserted into the transport chain, which conveys them without glass-to-glass contact to the downstream SME6060 (or, alternatively, to a discharge chute)

- Fully automatic system with the capacity to stack up to 88 syringe tubs

- Discharge chute for empty syringe nests, (or, alternatively, a stacker)

- Ultra-compact, modular machine design

- Needle guard systems are removed from Rondo trays and fed into the assembly station in a fully automatic process

- Assembly of plunger rods, backstops and needle guard systems including an extended flange, all on a single machine platform

- Full quality control ensures correctly applied labels and correctly inserted plunger rods

- To avoid reject containers and loss of production, our label application system works on the ZeroReject principle (a misprinted label is intercepted before it is applied)

- The label dispenser is modular and can be configured into up to two different label printing systems. The system offers a high degree of flexibility and enables easy printing of various label materials

- While the label dispenser has a compact design, it allows good access for loading label webs and changing label rolls

- To ensure high print quality and minimal waste, the printing and labeling areas are separated by an intermediate drive

- The system can be expanded to include a label splicer, allowing continuous production without machine downtime