// Are you in the business of processing cartridges and looking for an exceptional pharmaceutical product solution? Then B+S is the right partner for you. ///

- Our cutting-edge solutions offer maximum process reliability

- Smooth and gentle container transport

- Our two-phase dosing process ensures near bubble-free filling

- Our machines are designed for maximum ease of use and excellent accessibility, facilitating quick size changes

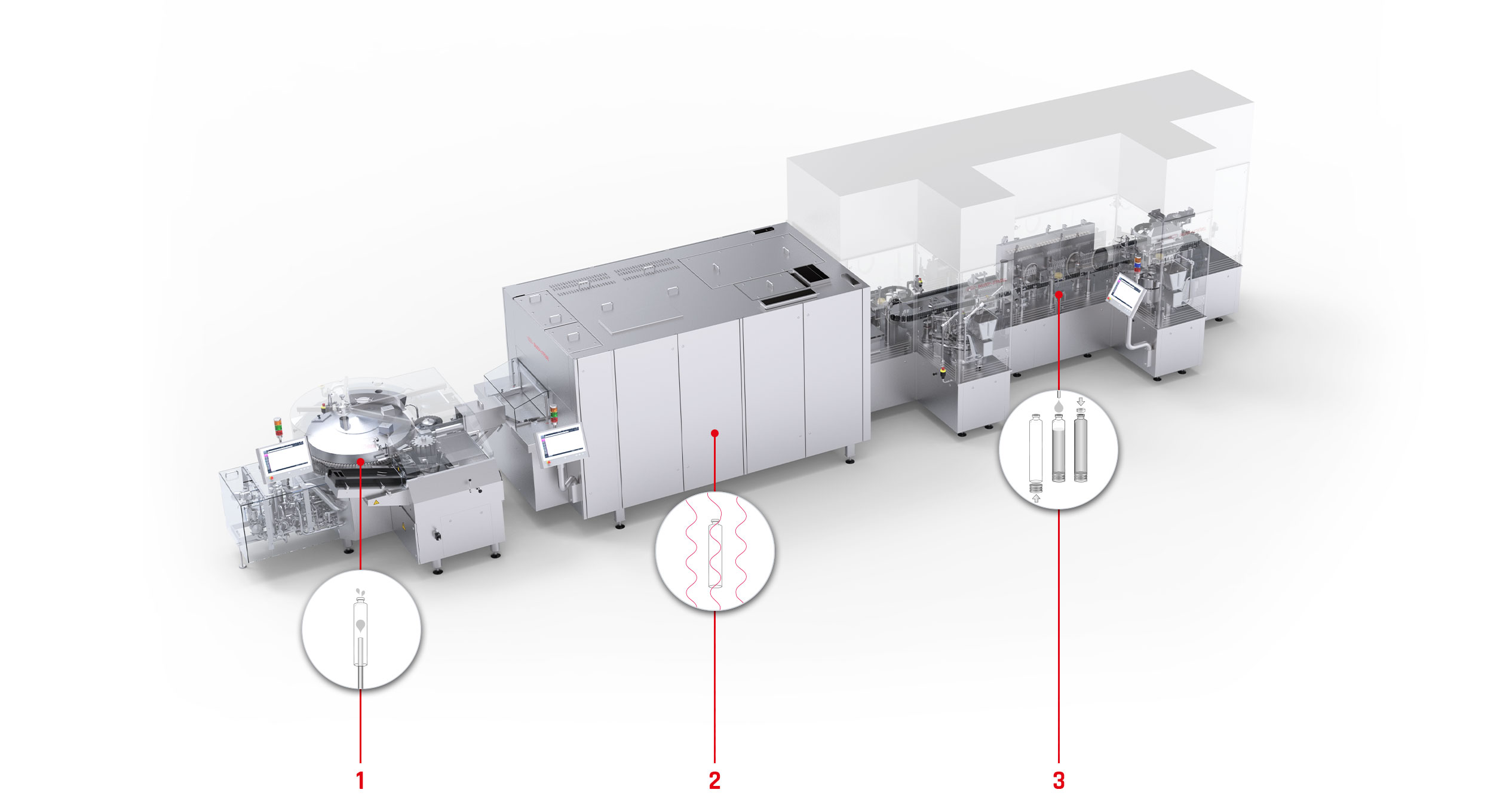

Rely on our extensive expertise and exceptional flexibility in developing and producing machines and systems for the bulk pharmaceutical processing of cartridges. Our efficient machines feature a state-of-the-art design that ensures maximum yield across all speed ranges, from low and medium to very high outputs. The standout features of our machines include their LF flow-optimized design and exceptionally high stopper insertion accuracy. Another notable feature is our dosing unit, known for its highly flexible combinability. Besides offering two-phase dosing and near bubble-free filling to the rim, our sensor-controlled fill level monitoring system eliminates the need for product extraction.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from our experience as a strong and dependable partner with a global network ready to support your needs.

Our 2,300-strong global workforce is dedicated to ensuring your success and providing you with support throughout the entire life cycle of your machines and production lines. We look forward to collaborating with you on the ideal solution for your product.

Our long-standing relations with leading pharmaceutical manufacturers are an ongoing testament to the trust we have built. You too can benefit from our experience as a strong and dependable partner with a global network ready to support your needs.

Our 2,300-strong global workforce is dedicated to ensuring your success and providing you with support throughout the entire life cycle of your machines and production lines. We look forward to collaborating with you on the ideal solution for your product.

- Our solutions for the intensive inner and outer cleaning of containers ensure the reproducibility of process steps at any time while allowing for rewashing

- Smooth and gentle container transport

- ECOwash conserves media resources and reduces noise emission

- Cleaning is fully configurable at each station along the line

- Cleaning media can be recycled to minimize resource consumption

- Safe and reliable sterilization and depyrogenation

- Gentle heating and cooling of glass containers

- Pressure cascade system engineered for maximum cost and energy efficiency

- Extremely long filter life (Longlife)

- Easy integration into production lines and facilities

- Enhanced process reliability through automated filter integrity testing (DEHS)

- oRABS, cRABS and isolator compatible

- Reliable and gentle container transport without glass-to-metal contact

- High-precision stopper insertion

- The insertion of mixing beads is ideal for products in suspension

- Gas-flushing stations

- Our dosing systems offer the highest level of accuracy for any product

– Rotary piston pump

– Peristaltic pump

– Time-pressure dosing - Choose from a range of SIP/CIP-compatible dosing components

- Option for combined processing of vials and cartridges

- Multiple discharge configurations are available