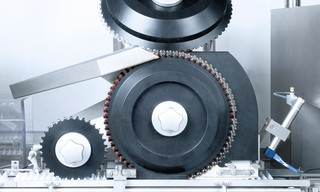

Process solutions

Bausch+Ströbel is your partner for pharmaceutical packaging solutions. You can find examples of our process solutions and their applications

here.

Product navigator

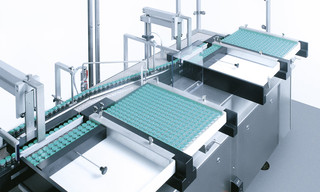

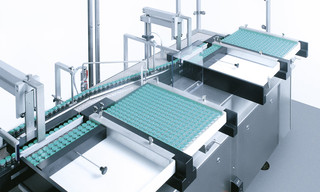

High-tech pharmaceutical packaging systems

The product navigator provides you with an overview of the series and machines available for your pharmaceutical application. On request, we will be pleased to examine the possibility of customized solutions, e.g. for similar packaging materials, specific process requirements, higher output etc.

Result(s) (42)

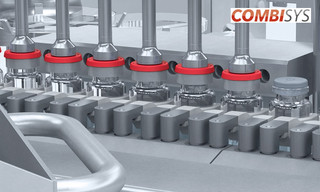

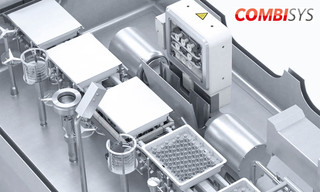

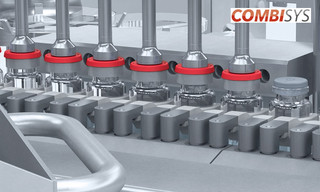

CombiSys machine

Container types

Max. output12,000 items/h

CombiSys machine

Container types

Max. output12,000 items/h

CombiSys machine

Container types

Max. output12,000 items/h

CombiSys machine

Container types

Max. output12,000 items/h

Container exterior cleaning machines

Container types

Max. output36,000 items/h

Cleaning machines

Container types

Max. output36,000 items/h

Cleaning machine

Container types

Max. output30,000 items/h

Cleaning machine

Container types

Max. output24,000 items/h

Filling and closing machine

Container types

Max. output36,000 items/h

Filling and closing machines

Container types

Max. output24,000 items/h

Filling and closing machine for plastic bottles

Container types

Max. output10,000 items/h

Filling and closing machines

Container types

Max. output24,000 items/h

Filling and closing machines

Container types

Max. output4,200 items/h

Filling and closing machines

Container types

Max. output60,000 items/h

Closing machine

Container types

Max. output4,200 items/h

Closing machines

Container types

Max. output36,000 items/h

Labeling machine

Container types

Max. output19,200 items/h

Labeling machines

Container types

Max. output48,000 items/h

Labeling machines

Container types

Max. output21,000 items/h

Labeling and assembly machine

Container types

Max. output4,000 items/h

Labeling and assembly machines

Container types

Max. output36,000 items/h

Lid and liner removal

Container types

Max. output360 tubs/h

Sealing the tubs (liner insertion and foil welding)

Container types

Max. output270 tubs/h

Tray-loading units

Container types

Max. output3,600 transfers/h

Nest loading

Container types

Max. output24,000 items/h

Syringe tray unpacker

Container types

Max. output24,000 items/h

Syringe nest unpackers

Container types

Max. output36,000 items/h

Buffer system

Container types

Max. output5,000 buffer capacity/h

Tub debagging machine

Container types

Max. output375 tubs/h

VarioSys module

Container types

Max. output3,600 items/h

VarioSys module

Container types

Max. output4,300 items/h

VarioSys module

Container types

Max. output4,500 items/h

VarioSys module

Container types

Max. output3,600 items/h