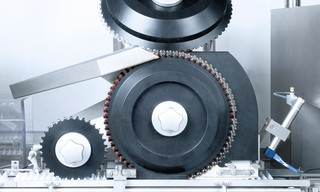

Cleaning machines

SWS series

The SWS cleaning machine is used for pharma-compliant wet cleaning of disposable syringes. The containers are conveyed through the work area very gently in an intermittent flow. By using the pressure-controlled rinsing and spraying system and various cleaning media, optimal pharma-compliant cleaning of all containers is assured. The order of use of the cleaning media is freely selectable. The line system is configured so that the different cleaning media do not mix.

HIGHLIGHTS

- Effective and thorough cleaning

- Pharmaceutical design

- Cleaning schematic is freely selectable

- Cleaning media cannot mix

| Type of machine | Output | Processing range |

|---|---|---|

| SWS1071 |

|

|

| SWS1080 |

|

|

Gentle container transport

Easy and centralized operation

- Water recycling station for the recirculation, regeneration and multiple use of a cleaning medium

- Preconfigured for a 3rd cleaning medium

- ECOwash – container-optimized cleaning needles

- System for silicone treatment of the glass inner walls of containers using atomizer nozzles

- System for silicone treatment of needles

- "no container – no silicone" check system

- Needle shield feed and application station

- Final insertion station for needle shields

- Needle passage check station

- Station to check for presence of syringe caps

- Station to check for bent syringe caps

- Purging of the water lines downstream of the cycle valve

- Pressure control

- Pressure monitoring

- Fine and HEPA filters

- Differential pressure monitoring system for filters

- Transition and linkage to machine downstream

- Service portal vision system (cleanroom compatible)

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)

The ECOwash system by Bausch + Ströbel ensures optimal cleaning of all containers while significantly reducing the consumption of cleaning media. This is achieved by using a combination of special cleaning needles which are developed and/or adapted in comprehensive trials to meet your specific requirements. The ECOwash (Efficient Customized Operation) technology has the following advantages:

- Optimized cleaning in hard-to-reach areas

- Reduction in water consumption: up to 40%

- Reduction in residual moisture content: up to 70%

- Reduction in air consumption: up to 20%

- Reduction in noise when blow-drying containers: up to 50%

- High energy efficiency